Stainless Steel Sintered Mesh Has High Strength and Filter Precision

Stainless steel sintered mesh is made of multi layers woven metal mesh by special laminated pressing and vacuum sintering process, which has high mechanical strength and rigidity.

With excellent corrosion and accurate filter precision, sintered wire meshes can be made into various filter elements.

Specifications of stainless steel sintered mesh:

- Materials: 304, 316L or customized.

- Thickness: 1.7 mm, 2.5 mm, 3.5 mm.

- Weaving type: plain weave, twill weave, dutch weave.

- Layers: three layers, five layers or multi layers.

- Filter shapes: rectangular sheet, round, ring, tube, cone, candle, pleated, etc.

- Filter rate: 0.2 μm–300 μm.

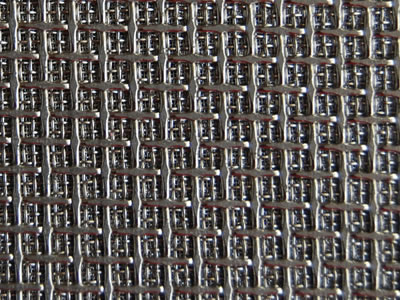

SINM-01: Sintered wire mesh is made of perforated sheet and woven meshes.

SINM-02: Stainless steel sintered mesh sheet has a solid structure.

Stainless steel sintered mesh applications:

- Different shapes of filter elements;

- Disperse cooling material in high temperature environment.

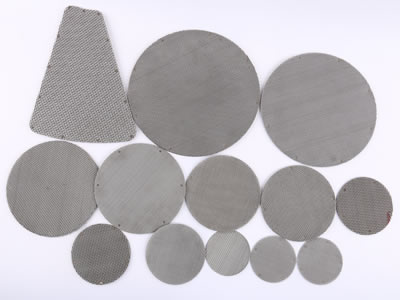

SINM-03: Sintered filter disc can be made into different sizes and shapes.

SINW-04: Ring shape sintered metal filter disc.

SINW-05: High precision sintered filter tube.

SINW-06: Sintered cylindrical filter element can be pleated shape.

SINW-07: Candle sintered pleated filter can resist to high temperature and pressure.

SINWM-08: Cone stainless steel sintered filter element.