Copper, Brass and Stainless Steel Shielding Mesh for Electromagnetic Shielding

SM-01: Shielding mesh can reduce the electromagnetic interference to equipment.

With the wide range of application and rapidly increase of electronic and electrical equipment in various fields, the electromagnetic interference is becoming more and more serious. some has affected the normal work of electronic devices. To solve these problems, we should shield these interference signal. The shielding devices can reduce the transmission of electromagnetic wave and cut down the interference to the devices and equipment. In this way, we can ensure the normal work of equipment, protect them and extend the service life. How to shield the electromagnetic wave, we recommended shielding mesh. Faraday cage is one of the effective shielding device.

Working principle of shielding mesh

Electromagnetic wave is composed of changing electric field and changing magnetic field. Changing electric fields generated magnetic field, and vice versa. The electromagnetic wave will not spread if there is lack of any one of them.

Shielding mesh is made of conductive metal. When the electric fields is formed around the shielding mesh, it will generate short-circuit electromagnetic force to destroy the formation of electric field. In the ideal condition, the resistance become zero, the electric fields will disappear.

When the electromagnetic wave enters shielding mesh area, the electric fields can not generate magnetic fields and then the spread way of electromagnetic wave is cut.

Note: the shielding mesh should be a closed system which will block the electromagnetic wave entering. If it is not, part of electromagnetic wave will entering because of the diffraction effect. The shielding mesh will have no shielding effect.

In fact. The shielding mesh must be grounded to ensure better shielding performance. Because when the electric fields reach, it is still able to form an magnetic field on the earth to form a new electromagnetic wave.

Material of shielding mesh.

- Stainless steel. It has excellent magnetic field shielding performance.

- Copper. 99.9% copper content. Best shielding performance among all shielding mesh materials.

- Brass. Alloy of copper and zinc. Excellent electric field shielding performance.

SM-02: Copper woven shielding mesh.

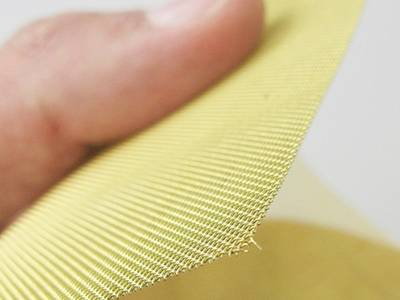

SM-03: Brass woven shielding mesh.

Specifications of woven type shielding mesh

- Material: stainless steel wire, copper wire, nickel wire and aluminum wire.

- Mesh size: 10 mesh to 200 mesh.

- Wire diameter: 0.05 mm to 2 mm.

- Roll width: 1 m, 1.2 m, 1.5 m, 1.8 m and 2 m.

- Roll length: 30 m, 50 m or 100 m.

Specifications of expanded metal type shielding mesh

- Thickness: 0.1 mm to 5 mm.

- Hole pattern: diamond.

- Hole size: 0.3 mm × 0.6 mm, 0.5 mm × 0.1 mm, 0.6 mm × 1.2 mm, 0.8 mm × 1.6 mm, 1 mm × 2 mm, 1.25 mm × 2.5 mm, 1.5 mm × 2 mm, 2 mm × 2.5 mm, 1.5 mm × 3 mm, 2 mm × 4 mm, 3 mm × 6 mm, 4 mm × 8 mm, 5 mm × 10 mm, 6 mm × 12 mm, 8 mm × 16 mm, 10 mm × 20 mm, 15 mm × 30 mm, 20 mm × 40 mm, 30 mm × 60 mm.

- Light transmission: 50% to 70%.

- Shielding performance: 50–60 db (frequency range: 100 MHz to 15 MHz)

Advantages of shielding mesh

- Electromagnetic radiation protection. It can effectively interdict electromagnetic, which is harmful to human being.

- Shield the electromagnetic interference and ensure the normal working of equipment.

- Prevent electromagnetic leakage and shield the electromagnetic signal passing through the display window.

- Good air permeability.

- Good light transmission.

- Soft structure for good ductility.

- Can be cut in to different shapes and sizes with no wire loose.

- Will not wrinkle.

Comparison of stainless steel shielding mesh and brass shielding mesh

In the near fields, the shielding can be divided into electric field shielding and magnetic field shielding. In the electric shielding, reflection loss is the most important, so we should choose the shielding mesh with high electric conductivity. Brass shielding mesh has better electric conductivity performance than stainless steel shielding mesh. So the brass shielding mesh is more suitable for electric field shielding.

In magnetic field shielding, absorption loss is small and reflection loss is also small because of magnetic field wave impedance is very low. In this situation, the shielding effectiveness will be very low, so we must choose the high permeability shielding material to improve absorption loss. The stainless steel shielding mesh has superior permeability than brass shielding mesh, so stainless steel shielding mesh is ideal for magnetic field shielding.

In the far field, plain weave is the main shielding target. We should take the absorption loss and reflection loss in consideration. Research shows that the brass shielding mesh has better shielding performance than the stainless steel shielding mesh based on the material. But if the two material has same mesh size, the shielding performance of stainless steel is superior to the brass shielding mesh.

SM-04: Stainless steel shielding mesh has better magnetic filed shielding performance.

SM-05: Brass shielding mesh has excellent electric field shielding performance.

Applications of shielding mesh

- Customs.

- Aerospace.

- Electricity.

- Information industry.

- Mechanical industry.

- Financial industry.

- High frequency medical facility.

- Measurement and detection.

- Military and government and secret authorities

- Other places where need good air permeability and good shielding performance.

- Other places where need good light transmission places.

SM-06: Copper shielding mesh for electromagnetic shielding.

SM-07: Brass shielding mesh room for electromagnetic shielding.

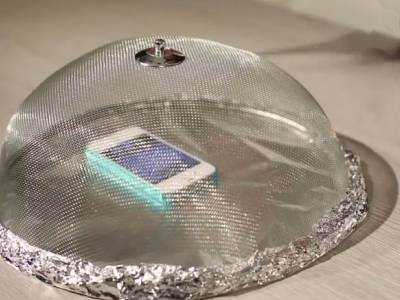

SM-08: Copper shielding mesh Faraday cage is used in laboratory.

SM-09: DIY stainless steel shielding mesh for phone signal shielding.

Except for the woven type, we can also supply the knitted mesh type, expanded metal type and perforated metal type for you. Just choose your satisfied products.

SM-10: Copper expanded metal mesh for electromagnetic shielding.

SM-11: Stainless steel knitted mesh gasket for electromagnetic shielding.

Typical specification of woven copper shielding mesh

Spec 1:

- Material: copper.

- Wire diameter: 0.011".

- Mesh size: 16 mesh × 16 mesh.

- Weight: 0.67 kg/m2.

- Function: it is similar to the insect screen typically used on residential windows.

Spec 2:

- Material: copper.

- Wire diameter: 0.025".

- Mesh size: 10 mesh × 10 mesh.

- Weight: 2.29 kg/m2.

- Function: it is heavier and stiffer than window screen.

Spec 3:

- Material: copper.

- Wire diameter: 0.014".

- Mesh size: 22 mesh × 22 mesh.

- Weight:1.24 kg/m2.

Spec 4:

- Material: copper.

- Wire diameter: 0.012".

- Mesh size: 20 mesh × 20 mesh.